Ask the Experts Soldering Q&A

I'm trying to solder Argentium Silver wire. Everything I have read says that I don't need flux, but when I soldered the wire it went black—like sterling—and didn't melt. Can you suggest a good flux and give some direction on how to solder?

- Nina

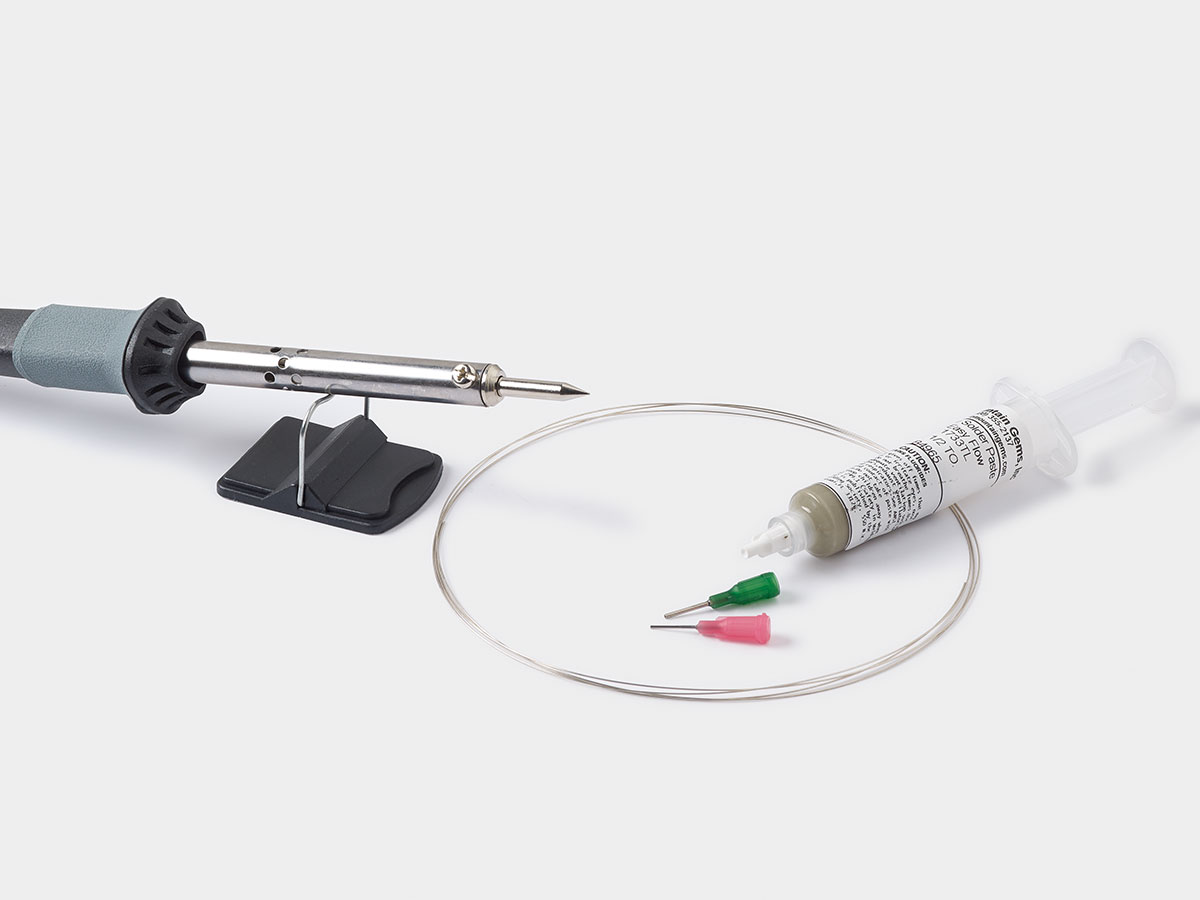

Argentium® sterling silver has a lower melting point (about 60 degrees lower than traditional sterling silver), so the solder should flow a little sooner depending on the grade of solder and technique. Use a liquid or paste flux to help any solder flow.

When soldering:

- Make certain the joins are clean and tight—that is, no air space between the joins

-This will allow any solder to flow, regardless of the type of solder

- 30-gauge Argentium solder sheets can be cut into snippets and used to solder joints

-This solder has been developed to eliminate oxidation at the solder joint

- There is no need to use a firescale retardant since Argentium is alloyed with germanium

-Germanium loves oxygen and forms a protective barrier over the surface of the metal, preventing oxidation and tarnish

- After heating the Argentium piece overall, concentrate the flame on the solder join itself and heat until the solder flows

- Let the piece cool down before quenching in water—shock cracks can occur if cooled too quickly

- Place the soldered item into a pickle solution (an acidic chemical solution) heated in a pickle pot

-The warm pickle will clean the metal of any oxidation (blackening) which may occur during the soldering

- Rinse in clean water

Note: Observe safety precautions with any chemicals and soldering techniques.

- Author Name

Shop for Your Materials Here:

Still can't find what you're looking for?

Submit Your Question