Work Hardening Metal

by Tammy Honaman, Author, Jewelry-Making Expert and Educator,

Exclusively for Fire Mountain Gems and Beads®

In this article, metal refers to the non-ferrous (not containing iron) metals used in jewelry-making—gold, sterling silver, sterling silver-filled, copper, brass, bronze and nickel.

Metal has the ability to be either rigid (also known as hard or full-hard) or malleable (also known as soft, dead-soft or fully annealed). There are levels of hardness between dead-soft and full-hard; this can be controlled to suit your design needs. Hard or soft, the temper is relative to the molecular structure of the metal at any given stage.

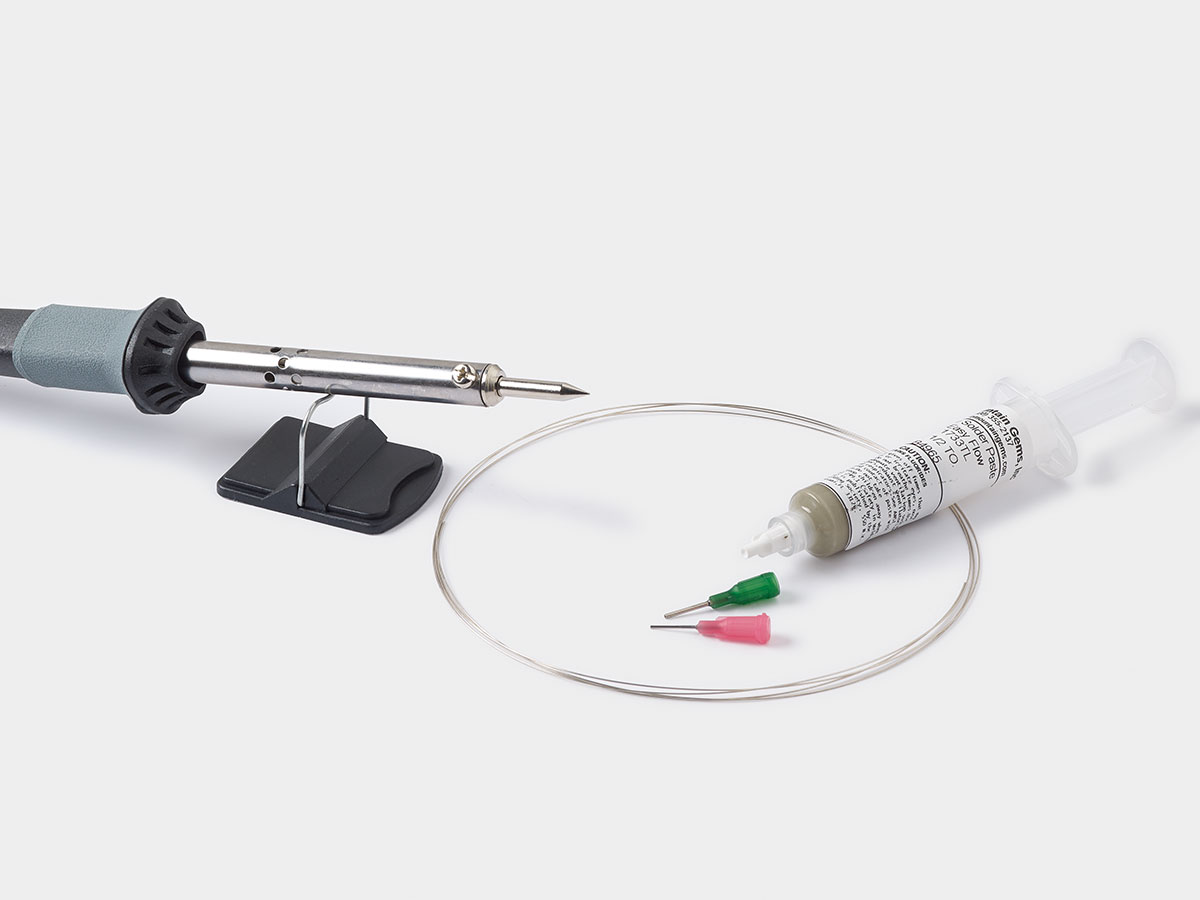

The molecular state of metal can be changed through heat. This action changes the molecules into a pattern where they have room to move, which allows the metal to move and be more malleable. The molecular structure also changes through working the metal in ways such as stretching, twisting, hammering, tumbling or just heating and allowing the metal to cool to room temperature. Each act brings varying levels of hardness, which in most cases makes moving the metal into your design more controlled and predictable. When pushed too far though, hardness can verge on brittle and eventually cause the metal to break, crack or chip. If you start to get close to this state, it’s time to heat the metal again to regain some of the malleability.

Each metal has different tolerances and each design dictates what works best for that design. A quick way to harden metal is by placing it onto a steel block and tapping it with a hammer or mallet. If you use a mallet, the action of tapping will affect the metal yet not mar the surface.

Another way to work-harden a design, something I find ideal when creating wireworked charm bracelets, is to tumble the piece in steel shot. This action not only hardens the metal and keeps the created wire shapes in place, it also helps to polish the surface of the metal.

Drawing wire through a draw plate will yield a harder temperament. Note: If you are drawing the wire down in size, anneal it first then draw through the plate.

Have a question regarding this project? Email Customer Service.

Copyright Permissions

All works of authorship (articles, videos, tutorials and other creative works) are from the Fire Mountain Gems and Beads® Collection, and permission to copy is granted for non-commercial educational purposes only. All other reproduction requires written permission. For more information, please email copyrightpermission@firemtn.com.