Know Your Beading Wire

Jewelry makers have a plethora of options for stringing beads, and beading wire is an excellent choice for designers seeking strength, durability and charm. Selecting the perfect wire to satisfy your needs can be challenging, so it's important to have some knowledge about beading wire. A few key factors to consider when choosing a beading wire are flexibility, resistance to kinking, strength and color.

Flexibility

If you want a better looking drape, choose a flexible beading wire that has a higher strand count. Silk cord has the ideal amount of flexibility and drape among stringing options, but wire can come pretty close to replicating the properties of silk.

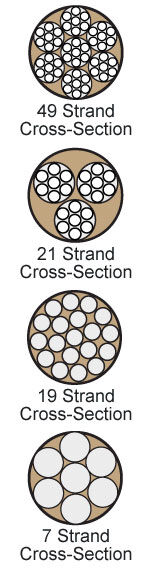

When beading wire is manufactured, it begins as a single solid wire (usually stainless steel) which is drawn through a series of increasingly smaller holes. The wire gets smaller and smaller, and it's heated and cooled to keep its flexibility. After many of these wire strands are drawn and treated, they are braided together and coated with clear nylon to create a single beading wire. A 49-strand beading wire is composed of 7 strands of 7 strands. The drape of a 49-strand wire is more pleasing than the drape of a 19-strand wire. Of course, the cost will increase as the number of strands increase. A 21-strand wire is a good choice for the crafter looking for quality and economy.

Resistance to Kinking

A necklace or bracelet wouldn't be very practical if it kinked every time it was folded into a jewelry box, so a wire's resistance to kinking must be examined. Just like flexibility, a beading wire's resistance to kinking has a direct relationship with the amount of strands it contains. Bend a wire with only 3 strands and you're in trouble. On the other hand, bend a wire with 49 strands and you won't be able to notice any kinking. To ensure you don't ruin a beautiful piece simply by folding it, invest in a wire with a higher strand count.

Strength

The tensile strength of a wire is important when beading a long or heavy necklace. If you choose a wire that isn't strong enough for your design, you can strain or even break a beading wire. For necklaces that are extra long or carry heavy beads, it's recommended to use the thickest diameter wire possible. The test weight or breaking strain (weight the wire can handle before failing) of a particular wire is normally provided on the packaging or the manufacturer's website. Wire composition also dictates the strength of the wire; stainless steel and plated stainless steel are the strongest, while sterling silver is the least sturdy wire.

Color

Color is an important factor in choosing beading wire, especially when you are beading with translucent beads. The gray color of raw steel might not harmonize with the beads or crystals of your design. If this is the case, there are many colors to choose from that will synchronize with your creation.

A product that meets all the requirements of great beading wire is Accu-Flex®. Accu-Flex is strong, flexible, kink-resistant, maintains a nice drape and is available in several materials and colors.

Shop for Your Materials Here:

Have a question regarding this project? Email Customer Service.

Copyright Permissions

All works of authorship (articles, videos, tutorials and other creative works) are from the Fire Mountain Gems and Beads® Collection, and permission to copy is granted for non-commercial educational purposes only. All other reproduction requires written permission. For more information, please email copyrightpermission@firemtn.com.