EncycloBEADia®

Alphabetical List of Jewelry-Making Terms

All

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

s

t

u

v

w

x

y

z

An iridescent mother-of-pearl harvested from certain saltwater mollusks. Paua shell is a variety of abalone.

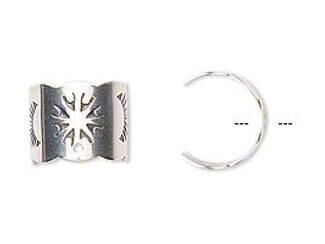

A horseshoe-shaped loop of metal used to cradle and protect beading wire, thread or cord from fraying through contact with metal components such as clasps or links.

A form of plastic which can be molded into a variety of shapes, including beads, components and findings.

A clasp which is extremely narrow, in order to allow large-hole beads to slide right over the clasp and onto the chain or cord. Can include Bayonet Clasp or Bead Clasp styles.

(see also Glue) A liquid, semi-liquid, gel or film that adheres or bonds items together. E-6000® and G-S Hypo cement are adhesives.

A clasp with a short length of chain that allows the wearer to vary the necklace length by attaching the clasp into different links of the chain. Can include Hook-and-Eye and Lobster Claw Clasp styles.

A blend of elements to create a new metal, usually in order to add strength and durability. Argentium™ silver is an alloy of silver, copper and germanium.

A form of bracelet, usually chain, worn around the ankle. Anklets made of leather or fiber are increasingly popular.

Heating metal in order to activate, increase or change its strength, hardness, ductibility and other traits.

Anodizing is a technique used in jewelry making to enhance the durability and color of metal pieces. By applying an electrolytic process, it thickens the metal's natural oxide layer, improving its resistance to wear and corrosion. This method allows for the introduction of vibrant, long-lasting colors to metals like aluminum, titanium, and silver, without the need for dyes, resulting in durable and aesthetically appealing jewelry.

An item, regardless of quality, which was manufactured 100 or more years ago.

Metal beads and components which have a human-created patina which alters the surface colors and gives the appearance of age.

(see also Antiqued) A patina created on metal beads and components that alters the surface colors and gives the appearance of age.

A framework around which a sculpture is built. Large metal and polymer clay pieces may use an armature to reduce kiln and oven times, and to stretch more expensive materials.

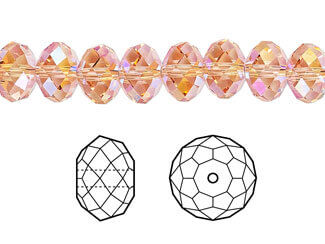

Named for the northern lights, aurora borealis is a term for crystal stones that have a highly iridescent surface. The effect is achieved by vapor blasting the facets of the lower part of the crystals with an invisible, micro thin metal sheet. Often abbreviated to AB, the term now refers to any highly iridescent surface.

The AB2X surface effect has two times the coating of the AB effect, covering the entire crystal. The iridescent rainbow effect is seen on all sides, producing the utmost sparkle.

A type of embroidery, sewing and needlework stitch where individual stitches are created in the opposite direction to the direction of the seam. Backstitch is usually utilized to outline shapes, add fine detail or embellish particular parts of a needlework project.

A metal loop that is used to attach a chain or cord to a pendant.

Bonds to any flat-backed item to make a pendant.

The trademarked name for synthetic resins and plastics developed by a US chemist. Jewelry pieces made of Bakelite were extremely popular in the US in the 1930s.

A clasp which uses pressure on the ball portion to keep the clasp closed.

An inflexible circular bracelet, often narrow in width. Some styles may be hinged, however most bangles have no clasp and must be slipped over the hand to be worn. It can be made of metal, wood, glass, plastic or other materials.

(see also Toggle Clasp ) An immensely popular two-piece clasp with one "T" shaped bar and a loop. The loop is usually a circle, but sometimes other shapes such as a star, heart, leaf or square are used. The clasp is closed by pulling the "T" shaped bar though the open loop, then releasing so the bar straddles the loop.

An irregularly shaped pearl, whether natural, cultured or manufactured. Can also refer to a highly-embellished artistic style from the 1600s to 1750s which included artists Caravaggio and Rembrandt (as well as musicians such as Bach and Vivaldi).

A tubular bead which is wider across the center and narrows at the ends, with a flat non-tapering end. It is shaped like an old wooden barrel, like those seen on old sailing ships.

(see also Screw Clasp and Torpedo Clasp) A low-profile clasp with a threaded closure, which is twisted or screwed to open and to close. Can include Bead Clasp styles.

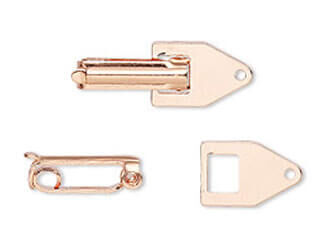

A clasp which looks like a bead and has a narrow bayonet closure.

A generally hard material, in any shape and small to medium size, which contains a hole for stringing.

Flat surface with channels used to design jewelry by offering a single or multiple channels. Some may be soft silicone, others may be flocked, in order to create a no-slip surface.

A bowl-shaped component used to "cap" one or both ends of a bead to add visual interest to a design. Mostly decorative, but can also prevent beads from rubbing against each other.

A clasp which looks like a bead and has a magnet, screw, tab insert or bayonet closure. Can include Barrel Clasp, Bayonet Clasp, Box Clasp, Magnetic Clasp, Screw Clasp and Torpedo Clasp styles.

Using traditional embroidery or sewing stitches to attach beads to fabric, leather or other surfaces. Bead embroidery is commonly used to embellish clothing, shoes and home décor, although there are designer-artists who create complex art using the technique.

Acrylic hook used for attaching beading to lampshades, curtain rods, serving bowls or shade pulls.

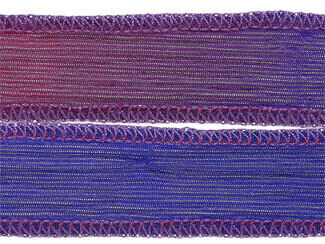

Beading wire is actually a cable composed of multiple strands of wire twisted together. It is much more flexible and stronger than single strand wire. The most common type of beading wire is made from braided stainless steel strands of wire and is nylon coated. Beading wire can also be made from other metals such as brass, nickel-titanium and sterling silver. Beading wire comes in a variety of different gauges or weights. Depending on the number of strands it contains, the flexibility will vary. A thinner wire will give an appealing drape to lightweight beads such as gemstone heishi and bugle or seed beads. A thicker weight wire should be used to accommodate larger, heavier bead strands and heavier usage. Beading wire does not hold a shape by itself and is not intended to replace the type of wire used in wire-wrap projects. Jewelry designs made with beading wire must be finished with crimps.

(also called beading loom) Frame designed to hold multiple strands of thread parallel. A piece of thread strung with seed beads in a predetermined order is run back and forth between every other thread to create a pattern.

A tool used to smooth or enlarge the drill hole in a bead, or to soften the edges of the hole. Bead reamers can be manual or electric. Specialized reamers are available for other materials--see Pearl Reamer.

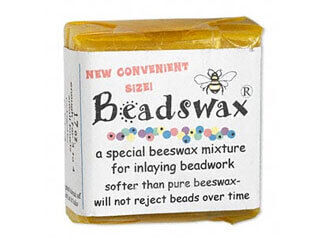

A mixture with a beeswax base, used for bead-based inlay work.

Weaving techniques adapted to create a flexible "fabric" out of seed beads and thread using a needle and thread.

Weaving techniques adapted to create a flexible "fabric" out of seed beads and thread. Seed beads are woven between the warp threads on a Beading Loom to create a design or pattern.

Wax from a beehive that is used during beading to make the surface of a thread smooth and slightly sticky. This keeps multiple fibers together for ease of beading and to give protection against fraying and water damage.

Multicolored agate necklaces worn in historical times by beggars, as it was commonly believed that agates attracted wealth.

A pair of chain-nose pliers with bent jaws, used to reach into tight places or odd angles, and grip beads or components. The bent tips allows access into difficult areas without blocking the line of vision.

The metal groove or flange holding a gemstone in its setting, or the slanting face of a cut gem.

A bead shape, most commonly seen in Crystal Passions®, of two cone shapes joined at the wide bases.

A cultured pearl originally non-nucleated, grown in a freshwater mussel from Lake Biwa in Japan. Only those actually produced there should be called Biwas; others are simply called freshwater cultured pearls.

Blister pearls are a pearly excrescence formed on the inside of the shell of a mollusk (oyster) commonly enclosing a foreign body, such as a bit of mud or parasite. Blister pearls are often irregular in shape.

(also called Bola tie or Bolo tie) A type of necktie popular in the American Southwest, created using a length of cord fastened with a clamping slide finding, and finished with metal bolo tip ends. The finding is often hidden by a cabochon, carving or other large design motif.

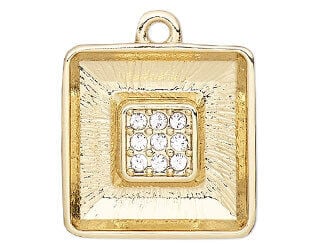

(see also Tab Insert Clasp) A clasp with a tab which is inserted into a decorative frame or box. Some styles come with safety latches or safety chains, which prevent the wedge-shaped tab from pulling out and the jewelry from dropping off. Some styles are accented with gemstones, enamel or inlay work. They are commonly used for lightweight necklaces, bracelets and anklets. Can include Bayonet Clasp, Bead Clasp and Filigree Clasp styles.

A box-like closed gem or stone setting.

A form of jewelry, usually decorative, worn around the wrist created from leather, fibers, plastics or metals. Bracelets can be embellished with stone, wood, shell or other materials. Some bracelets are used for medical or identification purposes (such as allergy bracelets).

An alloy of copper and zinc which creates a metal with a bright gold-like color.

(also called Cheyenne stitch or Comanche stitch) An off-loom bead-weaving technique used by many cultures across the world. In brick stitch, beads are woven together similarly to how bricks are stacked in a brick wall.

Bridge jewelry is the "bridge" between fine jewelry and costume jewelry. It may use vermeil, gold-filled or sterling silver metals and semi-precious stones.

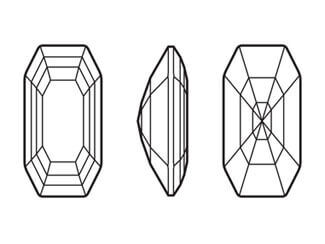

A briolette is an elongated, pear-shaped stone covered with bands of triangular or rectangular facets, usually with a pointed end and without a girdle.

An alloy of copper and tin which creates a metal with a dark golden-brown color.

A finding used to convert a brooch into a pendant. Styles are available for horizontal or vertical pins.

Brown-plated items have a polished copper core, dipped in a liquid brown compound (the recipe is a trade secret). The items are then baked to fuse the coating into the metal, slowly cooled, then polished again. Items can display a slight rainbow effect.

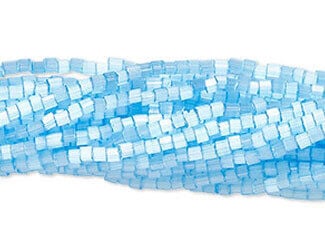

Tube-shaped glass bead in the same scale as seed beads, and often created by the same manufacturers.

1mm satin cord.

A clasp made of a matched set of buttons, one with a loop of cord. The leather is looped around the other button to close the clasp.

An undrilled gemstone with a smooth rounded top and a flat back. A cabochon is not faceted.

A carved gem or shell, in which the carved design stands out against a background of a different color.

Beads resembling old-fashioned candy sticks. Small canes of colored glass are fused together to create a larger rod, then coated with clear glass and fired. Most cane glass beads feature "lattichino"--thin white, clear or colored candy cane-like stripes. "Slicer" beads are smaller pieces, created from slices of cane glass.

The unit of weight used for precious stones. One carat equals one-fifth of a gram. Also a measurement of fitness in gold. Pure gold is expressed as 24Kt.The term ''carat'' dates back to the traders of the ancient world. A standard weight was required for precious gems as merchants of the ancient Mediterranean and Middle East were dependent on the ability to trade with a reasonably consistent unit of measurement. It was this need that led to the adoption of seeds and grains as widespread units of measurement.The carob seed and the wheat grain, both of which had been used for food purposes were found to be ideal units of weight. For centuries the carob seed remained the weight measurement for precious gems. By the Middle Ages, however, changes in the trade routes had occurred and large centers of trade were now found within Europe. The carat, as it had become known, became linked to 4 grains Troy weight, with the carob seed having been abandoned at some point during the shift of trade centers. The Troy carat was the equivalent of approximately 205 milligrams. This measurement of weight lasted for the carat until the 20th century. It was between 1907-1914 that the carat was married to the metric system of weights. By 1914 the United States officially abandoned the former Troy measurement of 205.3 milligrams for the carat, and adopted the current metric carat measurement of 200 milligrams.

A type of steel that contains carbon, with other alloys making up a trace portion. This term is also used generically to refer to steel that's not stainless.

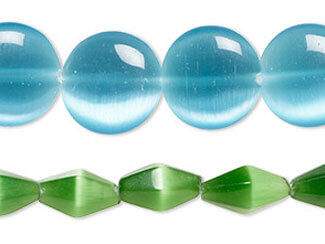

(also called Fiber Optic Glass) Created with manmade fiber optic glass, cat's eye refracts light in a way reminiscent of the oblong center of a cat's eye. This center appearance of movement is caused by chatoyance, which is defined as changeable luster or shine.

.jpeg)

Cathedral glass beads are made in the Czech Republic by pressing into a steel mold, coating with color then grinding and polishing every facet to reveal the base glass. The color coating remains on the ends, giving the appearance of bead caps.

Thermoplastic material that was commonly used in jewelry before the invention of injection molding. Now used to simulate tortoiseshell.

Used to describe a particular finish in seed and bugle beads. The use of Ceylon before a color name indicates the addition of a luster coating or the inside coloring of an opalescent bead.

A series of connected links, typically made of metal.

A pair of pliers with flat gripping surfaces, used to create reach into tight places, at difficult angles, to grip components, close jumprings, bend wire and stabilize a design while working. Available in both long-nose and short-nose varieties. Short-nose pliers offer more strength and stability and long-nose pliers give more reach.

A chain tab is a small, flat metal finding that is often hung on a piece of precious-metal jewelry and stamped as a "tag" that identifies the precious metal content.

Various types of colored quartz, usually with a milky appearance, including carnelian, agate, cat's eye and jasper.

Small ornaments worn as pendants or on bracelets.

An ornamental chain, pin or clasp, usually worn at a woman's waist, to which trinkets, keys, a purse, or other articles are attached. Also used to refer to pins with two figures linked together by a chain.

A particular shape of cut glass or crystal, most commonly known as Crystal Passions® rhinestones. A chaton is a faceted, pavillion-shaped (pointed) bottom. Some chaton styles have the same point on top, while others have a smooth domed top (similar to cabochons) or a flat top (similar to faceted gemstones).

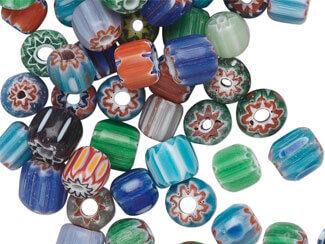

(also called rosetta beads or star beads) Glass bead style first created in Italy in the late 1400s. Chevron glass is composed of a varied number of consecutively-laid layers of colored glass. In between layers, the glass is pressed into a mold, to create the patterns within the beads. The glass is stretched to create a long tube, then cut into beads. Individual beads are then beveled or rounded at each end to reveal the chevron or star patterns in the glass. Only those beads with the internal structure exposed by beveling, cutting or grinding the end surfaces away are called Chevron Beads. All others are called rosetta or star beads.

A tight-fitting necklace that is worn close to the base of the neck. May be plain or with pendants or ornamentation. Measures approximately 16 to 18 inches.

A fastener in jewelry-making, which connects two or more ends of a piece of jewelry together, allowing it to be worn. Clasps can be utilitarian and purely functional, or highly embellished design elements. Clasps are available in most materials, including metal, gemstone, bone, wood and more.

Enamel with surface decorations set in hollows formed by strips of wire welded to a metal plate.

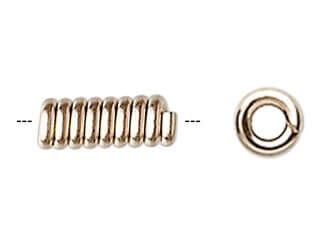

A bead created using coiled wire. Some styles can be pinched like a crimp bead.

(see also Cord Coil) A wire coil bead with an end loop.

A broad, choker-like necklace, consisting of three or more strands that fit snugly on the middle of the neck. Length is 14 to 17 inches. Known as a plaque de cou when attached by a front clasp. The style was popular in the 1960s, but was made fashionable by Queen Alexandra.

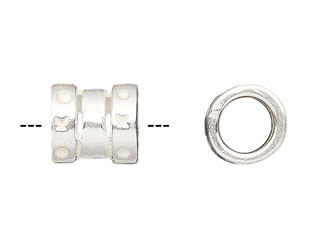

A smaller, self-contained part used in jewelry-making and beading.

Necklace terminator or beading finding used to bring multiple strands together at one point to attach a clasp or be part of the design.

A thin, flexible length of twisted fibers.

(see also Coil End) A wire coil bead with an end loop.

Costume jewelry is generally thought of as jewelry made from base metals, glass, plastics and other synthetics. It may also be comprised of shell, wood and other organic materials. Costume jewelry can be artisan-made or mass produced.

A shell, commonly white but also available in colors and patterns, which is smooth and glossy with a long, narrow, slit-like opening. Historically, cowries of different species have been used as a form of money. Additionally, the cowrie is used in a number of cultures as a symbol of childbirth, femaleness or womanhood.

(see also Crimp Bead and Crimp Tube) A metal bead or short metal tube used with all beading wires and some beading cords to secure the beginning and to finish the end of a strand. The crimp is pinched by specialized Crimping Pliers to create a secure piece of folded or crimped metal. It is then often covered by a Crimp Cover for reasons of aesthetics and wearing comfort.

A metal bead or short metal tube used with all beading wires and some beading cords to secure the beginning and finish the end of a strand.

A clasp containing structural crimps for attaching onto the end of beading wire or cord with Crimping Pliers. Can include Hook-and-Eye Clasp, Lobster Claw Clasp and Magnetic Clasp styles.

Pliers with specially-designed grooved opening for folding, rolling and smoothing crimp beads and tubes. Crimping pliers create a smooth rounded or curved crimp, rather than the flat piece of metal created with other pliers.

A metal bead or short metal tube used with all beading wires and some beading cords to secure the beginning and finish the end of a strand.

(see also Pony Bead) A bead cut from a tube of glass or plastic, then tumbled and polished to smooth the edges. Used on the bottom of cornrow braids, in fringe and for some Native American styles.

(also called leaded crystal or leaded glass) A material used by adding small amounts of lead oxide to molten glass in order to change its properties. Crystal glass has a higher density and increased light refraction, creating brilliant sparkling effects when cut.

(see also Quartz Crystal) Naturally occurring quartz in its clear or colorless form.

A brand name for leaded crystal glass. Crystal Passions® products are renowned for their color, brilliance and high quality.

Synthetic gemstone developed in 1977 to simulate a diamond.

A decorative closure used to fasten the two sides of a man's dress shirt sleeve. The finding is often hidden by a cabochon, carving or other design motif.

(see also Freshwater Pearl) Pearls created by a pearl farmer, who inserts a tiny piece, or "seed," of mother-of-pearl into a freshwater pearl oyster. The pearl oyster will coat the seed with progressive layers of nacre, creating a pearl.

(see also Saltwater Pearl) Pearls created by a pearl farmer, who inserts a tiny piece, or "seed," of mother-of-pearl into a saltwater pearl oyster. The pearl oyster will coat the seed with progressive layers of nacre, creating a pearl.

A form of chain with oval links that have been twisted, so that the entire chain lays flat.

(also called Bohemian glass or Bohemian crystal) Glass, usually in the form of beads, created in the Czech Republic. Historically, Bohemia was a district in the former Czechoslovakia and has been famous for its glass-making since the 13th Century.

A term used for wire that is extremely malleable and can be bent easily into a myriad of shapes.

Brand name for a variety of seed bead manufactured exclusively by Miyuki of Japan, using computer-controlled machinery to create extremely consistent beads. Delica seed beads are the same size in all dimensions, with large holes and thin walls. Some beads will be smooth cylinders, others will be six-sided "hex-cut" beads. Delica seed beads are popular with bead-looming and bead-weaving projects, as they create a finished product with a smooth and consistent surface.

A glass material containing ultra-thin layers of metal oxides. The micro-layers of metals and metal oxides create different layers and patterns of light refraction within the glass, causing a variety of colors to be displayed. Different angles of view alter which colors are displayed within the glass.

A flat component, usually round but also available in other shapes, with a large center hole. Named after the bakery doughnut, the donut component is most commonly used as a jewelry centerpiece.

A component within a piece of jewelry which dangles from another component or the main body of the jewelry and moves with motions of the wearer. A drop has one top loop or hole and any range of bottom loops or holes--including none.

A high-quality round pressed glass bead imported directly from the Czech Republic.

Name given to a layer of tiny quartz crystals which have formed on a gemstone.

Brushing a metal surface, sometimes with a matting punch or powder, to give it a duller (matte) finish.

A half-circle band or ring of metal which is pinched around the side or middle edge of the ear. The metal band or ring is often embossed. Some styles incorporate a dangle from the ear cuff, or a chain connected to an earstud on the same ear.

A finding, usually metal, used to create ear jewelry. The post or stud passes through the ear, and is secured by an earnut on the back. Also see Earstud.

A finding, usually metal, used to create ear jewelry. The post or stud passes through the ear, and is secured by an earnut on the back. Also see Earpost.

An earring form consisting of a short post with attached chain. The post serves as a "needle," allowing the chain to be threaded front-to-back through the ear. Includes a variety of lengths, chain types and embellishment styles.

A thin piece of wire used to support ear jewelry. Earwires come in a variety of styles. The most popular is the fishhook, which often comes with a ball or coil (or both), to balance the earwire in the ear.

Coating a metal surface (in fashion or bridge jewelry, usually with copper, nickel, chromium, gold, silver or rhodium) by means of electrolysis. The amount of electroplate on an object is measured in microns (one micron = 0.001mm). See also Gold Electroplating and Silver Plate.

The process of raising a domed design on the front of a piece of metal by beating it from behind with punches and a hammer.

Colored, opaque glassy material fused onto metal, pottery or glass.

A finding which allows for a bead, component or stringing material to be inserted or otherwise attached inside it. End caps can be used to create drops or to provide a professional attachment to stringing material.

A pair of pliers with metal-cutting blades, ideal for cutting thicker posts, pegs or wires.

A pattern made by cutting away the surface of metal, wood or other surface.

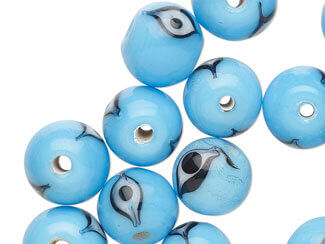

Decorated to resemble an eye, these beads date back to antiquity and have symbolic meanings. Often used in amulets.

A length of wire, usually straight, with a pre-formed simple loop at one end.

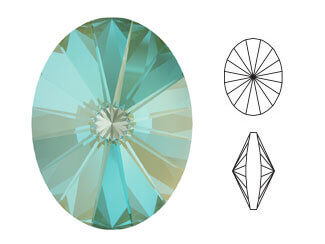

A flat surface or plane on a cut gemstone. The movement of light from one facet to another creates the sparkle and flash of a stone.

(also called Cat's Eye Glass) This glass gets its name from its similarity to Cat's Eye Quartz and the unique way the two materials refract light. The whitish "eye" or line resembles the oblong center of a cat's eye.

Lace-like ornamental work of fine gold or silver wire.

A clasp with an open, filigreed surface, like a metallic lace. Can include Box Clasp and Fishhook Clasp styles.

A jewelry-making term for any metal component used to connect and/or assemble jewelry. Findings are materials used to thread through, glue on, hook into, link onto or otherwise attach beads and components together. Findings include jumprings, clasps, bails, headpins, earwires and charms, to name a few.

Fine jewelry is generally thought of as jewelry that uses at least 14Kt gold or other precious metals and precious gems like diamonds, sapphires, rubies or emeralds. Fine jewelry can be mass-produced or artisan-made.

(also called fire polish) A process in which beads are machine faceted, then polished by glazing inside a red-hot glass oven. This softens the edges of the facets and gives the beads a smoother feel than machine-polished crystal beads. Fire-polished beads traditionally originate in the Czech Republic.

A lightweight clasp with a fishhook-shaped interior hook which is inserted into an oval box. The interior hook prevents jewelry from immediately falling off if the clasps are accidentally opened by hooking on the crossbar within the clasp box. Ideal for lightweight necklaces and bracelets.

A pair of pliers with smooth, flat jaws, used to bend wire, stabilize beads and components, flatten wire, create sharp corners in wireworking and more.

A pair of pliers used to trim headpins, eyepins, wire-wrapping wire and cable-style beading wire (such as Accu-Flex®). The outside surface of the curved blades create a flat, flush-to-the-surface cut--even in the tightest of places.

A liquid or paste used in metal soldering. Flux lowers the temperature of the two metal surfaces to increase bonding and protect the metal surfaces from oxidization.

Any item that is used as the central element in a necklace, bracelet or other jewelry design. A focal component is intended to be the main attention-getter, the "focal point." Examples include pendants, carved gemstone beads, cabochons in settings, etc. Sometimes referred to as a "station."

A thin leaf of metal placed behind a gem or stone to heighten its color or brilliance.

(see also Snap Lock Clasp) A low-profile clasp which is less likely to tangle or snag on clothes or hair than other styles. This hinged clasp folds shut, closing securely and locking with a quiet "snap." With this secure closure, snap lock clasps are ideal for bracelets or anklets.

(also called bullion) Tightly coiled, fine wire that forms a flexible tube. It is used by jewelry makers to conceal and protect stringing materials from abrasion by metal jewelry findings, especially the clasp. Also sewn onto fabrics in textile embellishment projects and used as a spacer material with high-end gemstone beads.

(see also Cultured Freshwater Pearl) Pearls created by a pearl farmer, who inserts a tiny piece, or "seed," of mother-of-pearl into a freshwater pearl oyster. The pearl oyster will coat the seed with progressive layers of nacre, creating a pearl.

A mostly round drop bead, created by Miyuki of Japan. Perfect for edges and the termination of a row of beadwork.

A bead which has been coated with a protective or decorative metallic coating.

The measurement of the thickness of wire or metal sheet: the higher the number, the thinner the metal. A 20-gauge wire or metal sheet will be finer than a 16-gauge wire or metal sheet.

A pair of pliers used to set or tighten the prongs on gemstone settings. The structure of these pliers gives them and parallel jaws and exceptional leverage.

A piece of mineral which, when cut and polished, is used to make jewelry, embellish clothing or create household décor. Some gemstone material is organic, such as amber, jet and pearl.

(see also Adhesive) A liquid, semi-liquid, gel or film that adheres or bonds items together. E-6000® and G-S Hypo cement are glues.

An electrolytic coating with gold or an alloy of at least 10% fineness to a minimum thickness throughout that is equivalent to seven millionths of an inch.

A gold alloy plate made by soldering, brazing, welding or other means that is not less than 10Kt fineness, where the plating constitutes at least 1/20th of the weight of the metal in the entire article. The term must be preceded by the karat fineness of the plating, such as 14Kt Gold-Filled. When using the term gold overlay, manufacturers are permitted to use a layer of gold that is less than 1/20th the weight of the entire piece, but they must stamp the proportion of the gold layer on the jewelry.

Also called Gold Color or "washed." The base metal is brass or steel and the product is electroplated with a non-standardized thickness of gold.

An alloy of zinc, tin and copper that results in a yellow the color of gold.

Items have an industry standard of .15 to .25 mils thickness of gold which is plated to the surface of the base metal.

The intricate ball patterns are created through a process called granulation. Tiny uniform ball shapes are fashioned into precision patterns, heat fused onto the surface, then carefully antiqued and polished, creating a visual masterpiece.

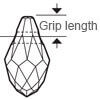

The depth of the grip range of an ice-pick bail. The grip length measures the distance of a stringing hole from the edge of a drilled focal, so a flat round with a hole 5mm from the edge will require a bail with a grip length of 5mm or more.

A bead with a drill hole that only goes halfway through. Half-drilled beads are attached to various settings using a glue or other adhesive.

Giving metal surface marks and textures by hammering.

A grouping of multiple strands of beads tied together. Many forms of seed beads are sold this way, especially Czech seed beads. The number of beads per hank is dependent upon the number of strands per hank, length of strand and beads per strand.

A length of wire, usually straight, with one flattened or embellished end. The flattened end prevents beads from slipping off the end of the pin.

This Pueblo Indian term is synonymous with thin, uniform, disk-shaped shell, gemstone and metal beads that are center- drilled and strung in a row.

A manmade material designed to resemble natural hematite, at significantly lower cost. Sometimes magnetized, or used as a base for a variety of finishes and coatings.

A gunmetal grey mineral form of iron oxide used in jewelry-making and décor objects. Sometimes magnetized. Believed to have metaphysical attributes.

A cord made from the fibers of the industrial hemp plant and commonly used in jewelry. Hemp cord can be used in its natural coloration, or dyed with bright colors. It knots easily, making it ideal for knotting or macramé projects.

Bead that is not a seed bead, with six sides. A hexagon bead is usually a flat bead, with a drill hole that runs from one of the six sides through the middle of the flat bead to the side directly opposite.

Seed bead with six sides, giving it a hexagonal shape. Available from many manufacturers, in a variety of colors, sizes and finishes.

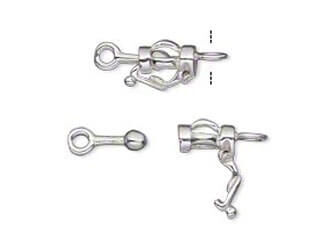

Also called Hook-Style Clasp. A clasp with a hook on one side and an open loop on the other. The loop is usually circular or oval, but other open shapes can be used. Possibly the oldest style of clasp in the world. Can include Adjustable Clasp, Crimp Clasp, Magnetic Clasp and Multi-Strand Clasp styles.

Bead and component material carved from the horns of animals such as cattle and goats. Horn is a permanent growth on the head of an animal. Antler is a material which is grown and shed yearly by wild animals such as deer, moose and elk.

Similar to a prong bail, it will create a loop to attach a chain to when the prongs are closed into a cross-drilled pendant.

To set pieces of wood or ivory, for example, into a surface, usually at the same level, to form a design.

Decoration made by carving or engraving a design into a gem or other hard material. Intaglio is the opposite of cameo.

An iridescent color, coating or finish on a bead which creates a play of colors on its surface. Similar to AB Finish, iris has a darker and shorter spectrum of color play.

(usually Wire Jig or Wireworking Jig) A plate or frame with moveable pegs used for creating standardized and repeatable wire-based jewelry components.

A piece of wire formed into a loop, usually round, and used to connect together jewelry components. Jumprings are sometimes offered in other shapes besides round, including oval, triangle, square and more.

The measure of fineness of gold. 24Kt is pure gold, 14Kt gold is 14 parts pure gold. The balance is alloy. 14Kt is the standard fineness used for most jewelry in the USA. Our 14Kt has a rich yellow color and has hardness and durability suitable for lasting use. Our 18Kt gold has a darker color with a deeper yellow tone.Karat MeasureGold/Alloy Content24Kt100% pure gold18Kt75% pure gold - 75014Kt58% pure gold - 58010Kt42% pure gold - 4209Kt37.5% gold - 375

A synthetic fiber used in bulletproof vests and adapted to jewelry-making for its high strength, especially in relation to its thickness. It is resilient to changes in heat.

A type of earwire which loops through the ear and has a small hook on the bottom to latch the wire closed for added security.

(the ''K'' is silent) The art of cleaving and shaping an object by chipping one stone against another hard object.

(also lampwork glass, lampworking, flameworking or torchworking) A type of glasswork, commonly seen in beads or focal components, which uses a gas-fueled torch to melt glass rods and tubes of glass to create patterns and designs.

An open-ended necklace that is held together by a flexible element such as a drop or ring. Length is 48 inches or longer.

A pendant with one stone, suspended from a necklace.

(also Hinged Earwire) A type of earwire which has a hinged locking mechanism at the bottom, for added security.

A component within a piece of jewelry which connects one component to another, or a single loop in a chain. A link has the same amount of loops or holes on each end.

A group of identical silver (or gold) tube beads strung in an uninterrupted group of strands. The multi-strand jewelry created this way gives the appearance of flowing or liquid metal.

A sulfur based oxidizing agent, used to create an antiqued finish on silver, copper and brass beads and components. Metals treated with this agent are given a blackened, vintage-style finish which is used to accentuate details and textures in bead and component surfaces.

A self-closing clasp in the general shape of a lobster's claw. However, this spring-loaded clasp is available in a range of shapes, sizes and styles.

(see also Bead Weaving, On-Loom) The process of using seed beads woven between the warp threads on a Beading Loom, to create a design or pattern.

A pair of pliers with an internal groove, allowing for the curvature of different sizes of loops. These pliers are used to smoothly close loops, jumprings, bracelet links and more without distortion, bending or scratching.

A process of casting wherein a wax model is encased in an investment, which is agitated mechanically or put into a vacuum to remove air bubbles. After the wax is burned off in an oven, a cavity remains, which is filled with molten metal through an opening. The investment is broken away from the hardened metal, which is then ready for polishing or ornamentation. For large scale production, numerous identical wax models are made by pouring molten wax into a rubber mold.

(also called lustre) A description of how light interacts with the surface of a material. Originally applied to gemstones such as the pearl or opal. The use of luster/lustre has been expanded to indicate a glossy sheen on other materials such as glass.

A technique of cord knotting which produces a rough, almost lace like band. Commonly used in jewelry and household décor, macramé popularly uses cotton, hemp, silk and leather cords.

A two-piece clasp containing one or more magnets. The magnets hold the two pieces of the clasp together, keeping the jewelry secure. Can include Bead Clasp, Crimp Clasp, Hook-and-Eye Clasp and Snap Lock Clasp styles.

A set of beads used by Hindus and Buddhists for prayer and meditation, similar to a Catholic rosary. Mala sets are usually made of a loop of 108 beads.

A cross with four broad arms of equal length, with tips that look like inward pointing arrowheads.

A broad bracelet in the form of a cuff.

A wood or metal form used to shape metal into a desired shape and size, or to size rings or wrist bangles.

A single-strand necklace ranging from 20 to 25 inches in length.

A dull finish, particularly on metals.

A steel wire which holds (or "remembers") its preformed circular shape. Available in multiple sizes to make necklaces, bracelets and rings. Memory wire jewelry does not require a clasp, using wire tension to keep jewelry on.

A unit of length equivalent to 0.001mm, used for measuring the thickness of electroplating.

Created by fusion of several glass rods arranged so that the cross-section creates a flower or pattern with a mosaic-like appearance.

A scale ranging from one to ten which rates the hardness of a gemstone or mineral in comparison with other minerals and gemstones. Talc rates as one, being one of the softest minerals. Diamond, the hardest substance on the planet, rates at ten.

An image or pattern created by using small colored pieces set in mortar.

A jewelry setting designed for the placement of faceted gemstones or cabochons.

1.5mm satin cord.

A clasp which secures jewelry with two, three, four or more strands. Some styles are accented with gemstones, enamel or inlay work. Can include Adjustable Clasp, Bar-and-Ring (or Toggle) Clasp, Filigree Clasp, Hook-and-Eye Clasp, Lobster Claw Clasp, S-Hook Clasp, Slide Lock Clasp and Springring Clasp styles.

A length of metal with a small hole on one end used to draw stringing material through beads and components, or used to draw thread through textiles, leather or other backing material.

A silver-white metal popular for plating because it is malleable and resists oxidation. The most common of metal allergies.

Items have an industry standard of .15 to .25 mils thickness of nickel which is plated to the surface of the base metal.

Items are made of an alloy, mostly containing nickel, popularized in German and Native American jewelry. Nickel silver resembles sterling silver in color, with a greyer tone.

A hypoallergenic metal first made to protect space vehicles from extreme conditions. After manufacturing, the base metal niobium is anodized to create 6 colors.

Large, tumbled freeform pieces of gemstone or glass.

A pair of pliers with attached nylon contact surfaces. Ideal for gripping round, square, twisted, coated, plated and precious metal wires during wireworking.

Nylon beading thread produced by the Belding Corticelli Company. Extremely fine thread popularly used in seed bead on-loom and off-loom bead weaving projects.

(also called Omega necklace) A type of neckwire where bands or links of metal are assembled on a wire or woven mesh. The embedded wire or mesh provides the structure and necklace strength, so the visible links can take on any design.

An especially long strand necklace. Length is 26 to 36 inches.

A term used to refer to a bead made of a carbon-based material. Many beads and other jewelry-making components comprised of pearl, wood, bone, horn and shell fall into this category. Also used to describe materials relating to or derived from living matter—for example, coral. Explore Organic products

Ribbon woven in a sheer fabric in a variety of colors.

The process by which the outermost layer of metal changes in color and consistency due to exposure to oxygen, creating a Patina. The antiquing process used to darken sterling silver and the green color of the copper Statue of Liberty illustrate the process of oxidization.

Palladium is a dense and lustrous, precious white-silver metal. A cousin of the platinum metal group, this rare metal is popular for fine metal jewelry.

The coloration that occurs in certain metals when they are exposed at length to the atmosphere. A thin, greenish layer appears on the surface of copper and bronze; a reddish effect on gold. An artificial patina can be created with acids or electrolyte.

The method of setting stones very close together so that very little metal shows between them.

Also called essence d'orient. A crystalline substance extracted from fish scales and combined with acrylic resins. Used to make imitation pearls. In better imitations, the essence is applied over opaline glass beads; in cheaper imitations, over plastic beads. Discovered in 1565 by Jaquin, a French manufacturer of rosaries, when he accidentally dipped some pearls into water in which he had washed fish. Refined versions today produce spectacular results.

A specialized file or hand drill used to complete or widen the drill hole in pearls.

An ornament suspended from a single chain.

A metal alloy that is largely made from tin with trace elements, like copper or antimony added for hardness. Older or classic pewter contains tin while lower grades of pewter may contain lead or zinc and have a darker silver-grey color. Newer or modern pewter uses antimony or bismuth rather than lead

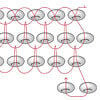

An off-loom bead weaving technique used by many cultures across the world. In peyote stitch, beads are woven together in a zigzag. Peyote stitch has both flat and tube-shaped variations.

A liquid applied to a metal surface that removes surface impurities (such as stains, scale, rust and more).

"Plated" refers to a process in which a thin layer of precious metal, such as gold or silver, is applied to the surface of another metal. This technique is used to give jewelry and/or components the desirable appearance of being made entirely from a more expensive precious metal, while keeping costs lower. Plating enhances aesthetic appeal, prevents tarnishing and increases durability. However, plated jewelry requires special care to maintain its appearance, as the thin layer of precious metal can wear off over time with regular use.

A rare grey-white metal (and element) used in jewelry. It is resistant to tarnish and wear-and-tear.

A precision hand tool used for a variety of purposes in jewelry-making: to hold objects firmly, to cut or bend wire, to crimp or flatten components and others.

The process in the last stage of metal finishing in which a rotating instrument is dipped in a polishing substance. Increases shine and eliminates flaws.

A plastic sculpting material made of polyvinyl chloride (PVC), used to create jewelry beads and components.

(see also Crow Bead) A bead cut from a tube of glass or plastic, then tumbled and polished to smooth the edges. Used on the bottom of cornrow braids, in fringe and for some Native American styles.

Created from ceramic material and fired at a high temperature, leading to a stronger and tougher bead or component.

A piece of broken pottery.

Rare and costly gems: diamonds, emeralds, rubies and sapphires.

A 17- to 19-inch length necklace.

A finding used to attach a chain to a cross-drilled pendant.

A technique used in metalworking used to harden steel by immersing in air, oil, water or brine (salt water).

2mm satin cord.

Patterns or decorations achieved with punches or chasing hammers.

A solid or semi-solid organic (carbon based) material, either natural or synthetic. In general, non-soluble in water.

Originally quartz from the gold washings along the Rhine river. Today, generally means colorless potash-and-lead glass that contains quartz in the form of melted lead crystal and is cut like a diamond. Also called strass, diamante.

An expensive whitish-gray metallic element from the platinum family.

A thin band of flexible material, usually fabric or thin leather, used for binding and tying. In jewelry-making, ribbon is used as stringing material, embellishment and more.

Necklace of stones, either all the same size or graded from a large central stone.

A round crystal component which is faceted to a point on both sides.

A small seed bead, sized at 15/0, manufactured by Miyuki of Japan.

A flat or disc-shaped bead. Typically round, rondelles are also available in square or triangular shapes.

Long, single-strand continuous necklace, 37 inches or longer.

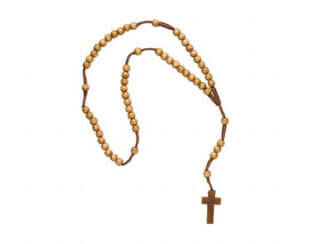

A particular configuration of beads and components used in the Roman Catholic religious belief. A number of rosary forms have occurred over time, such as the soldiers' rosary or the penal rosary. The word "rosary" has also been adapted as a general term for use when referring to prayer beads in other religions.

A pair of pliers created by blending Round-Nose Pliers with Side-Cutting Pliers. Round-Nose Pliers create round loops and curves. Side-Cutting Pliers cut wire smoothly.

A pair of pliers with round jaws, used to create curves and loops in a range of diameters in headpins, eyepins and other metal wire.

(see also Cultured Saltwater Pearl) Pearls created by a pearl farmer, who inserts a tiny piece, or "seed," of mother-of-pearl into a saltwater pearl oyster. The pearl oyster will coat the seed with progressive layers of nacre, creating a pearl.

A form of weaving that creates a material with a glossy surface and a matte back. Commonly used in formal dress material, ribbon and cording.

A long necklace, usually made of pearls or beads and often ending in a tassel. Popularized in the 1920s.

A scarab is a member of the Scarabaeidae family. This group of insects is made up of about 30,000 species of heavy oval-shaped beetles.A scarab is also a type of talisman made of stone, metal or other materials, in the shape of a scarab beetle. Scarab pendants and cabochons are often seen in modern jewelry, but were first hugely popular in ancient Egypt around 2,000 BCE. Finely carved scarabs were worn in ancient Egypt as jewelry and were also created for use as seals by individuals and government officials. The Egyptians also often buried scarab carvings with mummies, as it was considered a symbol of the soul.

A small pin usually a bird, insect, or flower worn in groups. Popular in the 1950s.

(see also Barrel Clasp and Torpedo Clasp) A low-profile clasp with a threaded closure, which is twisted or screwed to open and to close. Can include Bead Clasp styles.

A type of crimp finding featuring a screw inside the barrel that securely holds beading wire when

tightened. These crimps offer effortless adjustability, allowing you to easily tighten or loosen them as

needed.

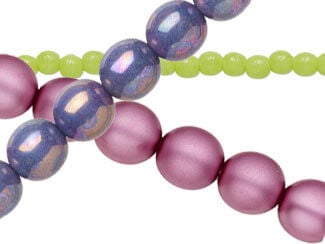

A uniformly shaped significantly small bead used for beading and jewelry-making. Seed beads are available in a myriad of colors, finishes and sizes.

Natural stones that generally have a lower value than precious stones, including amethyst, aventurine, carnelian, garnet, opal, rose quartz and others. Primarily used in fashion jewelry.

A frame, container or cage designed for the placement of faceted gemstones or cabochons.

A double-ended clasp shaped like an "S." Available in a spectrum of sizes and styles; some clasps are sold with two rings. Pinching the arm of the "S" secures the clasp. Pulling the "S" open again releases the ring and opens the clasp.

Three different scales ranging from 10-100 for measuring the resistance of gels, rubbers and plastics to indentation. Shore A00 measures very soft rubbers and gels. Shore A measures flexible rubbers to semi-rigid plastics. Shore D measures hard rubbers and semi-rigid to hard plastics.

A mechanical bonding with a silver alloy of at least 92.5 percent fineness. The bonding must be equal to at least one-twentieth of the metal in the article. This can also be called silver overlay, but never silver plate.

Also called Silver Color or "washed." The base metal is brass or steel and the product is electroplated with a non-standardized thickness of silver.

A fine silver film deposited on a base metal by electrolysis, in the same kind of electrically-charged bath used to make gold electroplate. The film can be as thin as seven millionths of an inch. A silver plate item cannot be called sterling or bear a marking of "silver."

A fine silver film deposited on a base metal by electrolysis, in the same kind of electrically-charged bath used to make gold electroplate. The film can be as thin as seven millionths of an inch. A silver plate item cannot be called sterling or bear a marking of "silver."

(see also Multi-Strand Clasp) A clasp consisting of a set of tubes, one of which slides inside the other and locks into place. The bar style of these multi-strand clasp holds almost an unlimited number of strands of chain, cord, beading wire or thread.

(see also Fold-Over Clasp) A low-profile clasp which is less likely to tangle or snag on clothes or hair than other styles. This hinged clasp folds shut, closing securely and locking with a quiet "snap." With this secure closure, snap lock clasps are ideal for bracelets or anklets.

Jewelry finding used to hold multiple strands of beads in alignment and prevent tangling, are inserted at intervals while stringing the beads.

Double-wire ring findings, similar to those found on a keychain, used to connect jewelry-making components. Used when security and strength in a ring is paramount, as it is both stronger and bulkier than an equivalently sized jumpring.

A pair of pliers with a small hook on one tip, designed to open split rings just enough to slide them onto a finding. The split ring can then immediately close without distorting or warping the metal out of shape.

A popular spring-loaded clasp used with a jumpring or chain tab. It comes in a multitude of sizes, for single-strand to multi-strand designs.

As defined by the American Gem Trade Association (AGTA), stabilization is the use of a colorless bonding agent (commonly plastic) with a porous gemstone to give it durability and improve appearance. Turquoise is a commonly stabilized gemstone.

The generic term for grades of steel that contain more than 10% chromium, with or without other alloying elements. Stainless steel may also have varying additions of nickel, molybdenum, titanium, niobium and other elements. Stainless steel resists corrosion, maintains its strength at high temperatures, and is easily maintained. The chromium in the steel combines with oxygen in the atmosphere to form a thin, invisible layer of chrome-containing oxide. The most common grades of stainless steel are:TYPE 304 - The most common type (chromium-nickel stainless class): accounting for more than half of the stainless steel produced in the world. This grade withstands ordinary corrosion in architecture, is durable in typical food processing environments, and resists most chemicals. Type 304 is available in virtually all product forms and finishes, including jewelry components.TYPE 316 - Also a chromium-nickel stainless class, 316 contains 2%-3% molybdenum (whereas 304 has none). The inclusion of molybdenum gives 316 greater resistance to various forms of deterioration.

A pendant that is the focus of a design.

Items are made of 92.5% pure silver and 7.5% copper or other alloy, proportions fixed by law. Sterling silver will "patina" in time, that is, its color will take on an "antique" look.

Items are made by combining a durable outer layer of sterling silver (.925/20) surrounding a copper-alloy core. Fabrication is completed with an anti-tarnish coating to preserve the beauty. Sterling silver-filled items handle like sterling silver.

A straight pin worn vertically on a scarf or tie, which has some kind of ornamentation on the top. Explore Stick pin products.

A form of the Lobster Claw Clasp. The swivel allows the design to twist 360 degrees while the clasp stays in place, so they are ideal for bracelets and anklets.

An easy-open clasp which closes by inserting the decorative tab into the slot of the other half of the clasp. This easy-open, easy-close style is held closed by the weight of the finished jewelry itself. Due to their ease of opening, they are recommended for necklace designs.

Jewelry constructed entirely of metal and without stones. Introduced by Alfred Phillippe, who drew for Trifari.

A heat treatment used for metals and glass. Tempering is used to toughen steel and change the breakage effect in glass. Tempered glass is used for automobile windows, glass tables, lab equipment and more.

Bond to one end of a flat bulk chain to create a jumpring attachment.

A length of fine string composed of several fibers twisted or spun into a single strand. Thread can be made of natural fibers (such as silk and cotton) and manmade fibers (such as nylon and Kevlar). Thread that has been woven (or braided) into a thick tube (or flat strand) becomes Cord.

A non-toxic, hypoallergenic synthetic polymer material used to coat beading thread. It binds thread fibers and prevents fraying--straightens, strengthens and weatherizes. It adds a thin, even, slick coating to thread so beads slide easily and produces a small static charge which dramatically reduces tangling. It won't stick to beads or needles and does not attract dust or clog bead holes. It doesn't tarnish silver-lined or metallic beads.

A miniature braided stainless steel cable-style wire used for jewelry-making. Tigertail has a nylon coating, which protects the steel wire from corrosion or wear, and is stiff enough to be strung without using a beading needle. Tigertail is secured with a crimp bead, crimp tube or crimp clasp.

Tin is a pure metallic element, listed on the periodic table as Sn (an abbreviation of Stannum, which is Latin for tin). Tin resists oxidization and corrosion, so it is commonly used in metal jewelry components. Tin is found in alloys such as bronze (a mix of copper and tin) or genuine pewter (a mix of tin with copper, antimony and lead). Tin is also used as an anti-corrosion coating over steel, in solder and in some batteries.

items are made of neutral grey, lightweight metal. After manufacturing into the desired shape, such as earposts, the neutral grey base metal titanium can be anodized into six colors. (Note: anodized titanium earstuds are not certified hypoallergenic, however most metal-sensitive people can wear them comfortably.)

(also called bar-and-ring clasp or T-bar clasp) A style of clasp consisting of a loop (usually a circle, but sometimes other shapes such as stars, hearts or leaves); the other piece is a ''T'' shaped bar. The clasp is closed by pulling the ''T'' shaped bar through the open loop. Immensely popular and easy to use, the toggle clasp is available in almost infinite material options and in a variety of styles, weights and designs. They are commonly used for necklaces (especially lariat style), bracelets and anklets.

(see also Barrel Clasp and Screw Clasp) A low-profile clasp with a threaded closure, which is twisted or screwed to open and to close. Can include Bead Clasp styles.

A popular choker-type, multi-strand necklace in which the strands twist around each other.

The weight system used for precious metals, differs from a standard avoirdupois ounce, the weight system used for food and non-precious metal items. Only precious metal uses the troy ounce system. One troy ounce = 31.1 grams. One avoirdupois ounce = 28.4 grams.

A hinged clasp which is hooked through each end of a continuous necklace, or opera-length pearl strand, changing it into a twisted choker necklace.

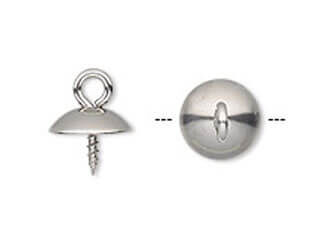

Finding that can be bonded to round bead or tumbled stone to add a loop and create a pendant.

A glass bead in the style of the glass artists of Venice. Venetian glass beads are famous for their color, craftsmanship and quality. Also called Murano glass.

items are made of sterling silver, electroplated with gold. Vermeil has an equivalent of 2-1/2 microns of 24Kt gold. Fire Mountain Gems carries ''vermeil'' style gold-finished beads in different karat colors.

Vitrail is a translucent color-coating effect that is vacuum- sealed onto the reverse side of glass and crystal beads, creating a kaleidoscope of color.

Alloys with heavy tin or lead content, such as pewter. Also called Britannia metal or tin plate. One of the most commonly used metals in costume jewelry.

(also called Accu-Guard™ or wire protector) A horseshoe-shaped loop of metal used to cradle and protect beading wire, thread or cord from fraying through contact with metal components such as clasps or links.

A pair of pliers with designed with a stepped round tip, in order to make consistent 4mm, 6mm and 8mm loops or jumprings.

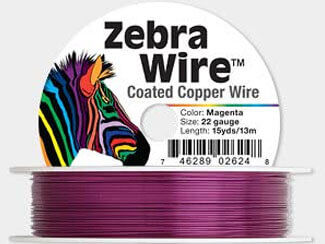

Zebra Wire is a copper wire designed for fashion jewelry, crafts and home décor projects. Colored Zebra Wire is made by electroplating a copper wire core, spraying the copper with a vibrant enamel coating, and applying a protective lacquer. This coating process is repeated to produce a strong, glossy, non-tarnish finish. Both flexible and durable, Zebra Wire is tempered dead-soft. It can be bent into shapes, wraps well and can be woven. It will stay wrapped and will hold its shape similar to sterling silver dead-soft wire.To maintain the integrity of the coating, the use of Tool Magic covered pliers and/or nylon jaw pliers is recommended when working with colored Zebra Wire. Use a polishing cloth, such as Moonshine® cloth, to bring back luster that might have been lost.The metallic colors of gold, silver and natural Zebra Wire are not enameled. Gold color is made of raw brass; silver color is copper with a silver finish; natural is made of raw copper.Zebra Wire colors include black, brown, green, magenta, red, sapphire, natural copper, silver and gold. Gauges available are 12, 14, 16, 18, 20, 22, 24, 26, 28 and 30.

Zinc is a pure metallic element commonly used in metal jewelry components. Zinc is found in alloys such as brass or used as an anti-corrosion coating.

Originally a term from ancient Greek astronomy, "zodiac" described the constellations which are on the path the sun takes across the sky over the course of a solar year. Those constellations were each eventually assigned to one of 12 months, forming the western zodiac popularly known today. The word has also been used to refer to the Chinese zodiac, which uses animal symbols in a cycle of 12 years (instead of 12 months).