Accurate Measuring in Jewelry-Making

by Sandra Lupo, Metalsmith, Jewelry Designer and Instructor,

Exclusively for Fire Mountain Gems and Beads®

Take the guesswork out of your wireworking and metalworking projects as well as save money and time by setting some measuring rules right from the start of your design project. To achieve your best design and implementation:

- Minimize waste when cutting. The phrase "measure twice cut once" applies here.

- Use quality measuring tools so your work will be precise

You'll be a happier jewelry maker when your results are what you set out to create, whether it is consistently similar, graduated or accidentally-on-purpose components.

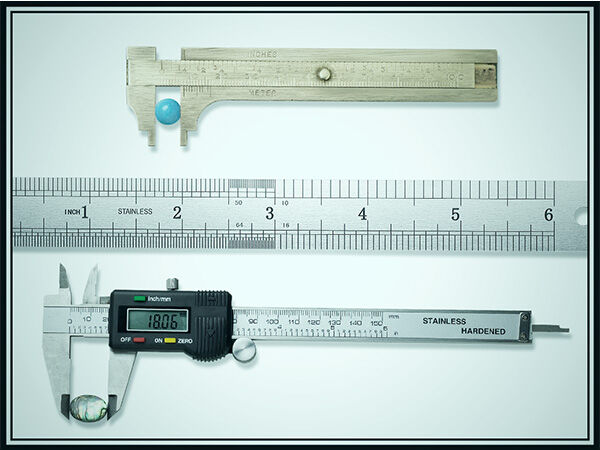

Measuring Devices

Save valuable time and effort by selecting the best quality you can in linear rulers, metal gauges and digital calipers.

Sturdy metal gauges give a more exact read on the size of wire, thickness of sheet and the millimeters of beads and cabochons. Take the time to learn how to read a ruler, sliding or wire gauge and how they relate to the materials you are measuring.

To measure professionally, go with a digital caliper--it does it all for you. This compact device is battery-operated and so easy to use for measurements and conversions. I'm hooked on mine!

Cutting Tools

There are three main cutters used in metalworking: flush-cutters, end-cutters and shears.

Flush-cutters are widely used for wireworking projects. This type of cutter will provide a flush or blunt cut exactly where you've made your mark and with little pinch to the wire. You want flush ends as this eliminates burs or diagonal points which might scratch or catch clothing, and for a better fit when wire ends meet. A good example of this would be the wire ends of a jumpring. Here, in order for a jumpring to close properly, the ends need to be flush so they meet well and provide the best join possible without soldering.

The cutting rule for flush-cutters is to place the back of the cutter (the flush side) against the measured piece to be cut. The back side of the blade cuts the flush end on the working wire end with the portion that falls away having the pinched or pointed end. You may still need to use a jeweler's file to file down the cut wire ends, but starting with a flush cut will help expedite the filing process as there will be little work needed.

End-cutters and shears are used in wire and sheet metalwork projects and offer clean cuts in tight areas. In the case of metal sheet, precise cuts along measured and marked lines limit waste and help expedite the fabrication process.

Measuring Resources

When creating a design from one of the many instructions found on the Fire Mountain Gems and Beads website or in one of the jewelry-making books available, there are measurements that need to be followed to replicate the design accurately. Sometimes the measurements need to be converted to work with the tool you are using for measuring your materials. To help with measuring conversions, view the below charts:

- ''Metric Conversions'' chart

- ''Wire Gauge to Inches and Millimeters Conversion'' chart

Jewelry-making books, magazines and other published literature offer a basics section and conversions from standard to metric. These basics sections also offer invaluable measuring, cutting and forming tips. A highlight would be to measure the first piece (of wire) and cut the rest of the pieces to that first piece to ensure exactly sized components. Another great tip is to cut and form wire segments in assembly-line fashion for speed and accuracy in completing the project.

Shop for Your Materials Here:

Have a question regarding this project? Email Customer Service.

Copyright Permissions

All works of authorship (articles, videos, tutorials and other creative works) are from the Fire Mountain Gems and Beads® Collection, and permission to copy is granted for non-commercial educational purposes only. All other reproduction requires written permission. For more information, please email copyrightpermission@firemtn.com.