EnviroTex® Jewelry Resin

Instructions

EnviroTex Jewelry Resin

Professional results are easy to achieve with EnviroTex Jewelry Resin! This product adds depth and crystal clear clarity like no other. It visually enhances the surface on which it is applied, resulting in brighter, deeper and more intense colors. EnviroTex Jewelry Resin has amazing bubble release. It is easy and fun to use and has a pleasing citrus scent! Formulated for high resistance to light exposure and UV rays from the sun. When cured, the resin coating is extremely durable, waterproof, heat and chemical resistant. EnviroTex Jewelry Resin cures to a soft cure in 12 hours, medium cure in 24 hours and hard cure in 48 hours.

Preparing and Protecting Your Work Area:

- Work area should be dry, level and free of dirt or dust.

- Room temperature and jewelry pieces should be between 70°F / 21°C and 80°F / 27°C.

- Work surface should be protected with a plastic sheet, wax paper, or disposable plastic bag.

EnviroTex Jewelry Resin Tips:

- Paper and Photo inserts: Cut paper or photo to fit bezel and glue in place with white craft glue. Allow glue to dry then seal the surface of your paper or photo with two thin coats of white craft glue. If paper is not sealed properly, the EnviroTex Jewelry Resin can seep into the paper/photo resulting in blotchy or semi-transparent areas. Make sure the craft glue dries clear between coats and complete dry before coating with EnviroTex Jewelry Resin. The glue used for sealing paper/photos can also be used to glue down any charms, found objects, etc., into the bezel.

- Found Objects such as Stones, Glass Chips, Watch Parts, Shells, Dried Flowers, Wood Pieces, etc: There are any number of objects that can be added to jewelry bezels to create an endless array of patterns, textures, etc. One of the best ways to add these items is to pour a small amount of mixed EnviroTex Jewelry Resin into your bezel. Then place and arrange your objects. Check for bubbles around the base of these pieces and dislodge with a toothpick if necessary. Absorbent materials such as wood, leather, fabric, etc., mustbe pre-sealed with two thin coats of white glue. Allow glue to dry clear between coats and before inserting into bezel.

- Adding Pigments, Dyes, Metallic Powders, Oil and Acrylic Paints: At times you may want to add color to your jewelry pieces. You can add Castin’Craft® Opaque pigments to mixed Envirotex Jewelry Resin for a solid color look or Castin’Craft® Transparent Dyes for a translucent glass effect. Metallic powders, Acrylic or Oil based artist paints can also be added. Use a toothpick to disperse pigments, dyes, powder or paint into mixed EnviroTex Jewelry Resin. Be careful, adding too much can have adverse effects on the hardness of the final cure.

- Epoxy Clay and Polymer Clay Jewelry Resin pieces: EnviroTex Jewelry Resin is ideal for coating these types of clay products. Epoxy clay pieces can normally be coated without sealing. Some polymer clays have an oily surface and should be pre-sealed with a fast drying acrylic spray prior to coating.

Application:

Important: EnviroTex Jewelry Resin performs best at temperatures between 70°F / 21°C and 80°F / 27°C. Both resin and hardener bottles should feel slightly warm to the touch, if they feel cool, they should be warmed by placing them in warm tap water (not hot) for 3 to 5 minutes prior to using. If bottles become overheated, allow them to cool before using. Never mix hot resin and hardener together! Mixing EnviroTex Jewelry Resin when cold can result in cloudy pieces with microscopic bubbles.

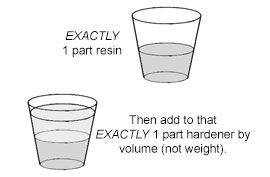

Measure: EnviroTex Jewelry Resin is a reactive 1 to 1 ratio epoxy and therefore must be measured accurately. With a pen or felt tip marker, make two measurement marks on the clear measuring cups provided, one for resin, the other for hardener. Make sure the measurements are equal in volume. Next, measure resin to the first mark, then hardener to the second mark (example 1/2 oz. + 1/2 oz. = 1 oz.). = 1 oz.).

Important: Do not vary the 1 to 1 ratio for any reason! Failure to measure equal amounts of resin and hardener can result in soft or sticky pieces. Never pour the entire contents of both bottles and expect properly measured amounts, always measure!

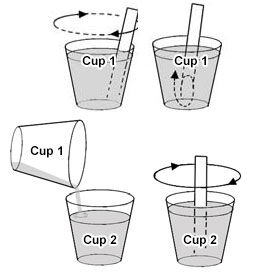

Mix: For EnviroTex Jewelry Resin to chemically blend, it must be mixed together in two stages. With the resin and hardener in one cup, use a stir stick and mix together for two full minutes. During mixing, use the stir stick to scrape the sides and bottom of mixing container. Occasionally scrape the mixture from stir stick back into the solution. After two full minutes of mixing, pour the contents into the second container provided. Using a new stir stick, mix the contents of the second container another minute, again scraping sides of container and stir stick. Use only product from the second container.

Open or Working Time: EnviroTex Jewelry Resin has about 25minutes working time at 70° F. In most situations this is more than enough time to complete your projects.

Tip:

- If longer times are required, immediately upon mixing, pour the mixture out onto a disposable plastic sheet.

- Pick up material as needed with a stir stick or plastic spoon. This keeps the material from prematurely setting up and provides a longer open time.

Apply:

- a. Jewelry Pieces: Use a brush to apply as required. Arrange pieces on a plastic sheet or wax paper while curing.

- Tip: Some pieces may require them to be held in a certain position while curing. You can use plasticine clay for this. Arrange prior to coating. Dispose of brush when finished.

- b. Filling Bezel: Dip your stir stick into the mixed EnviroTex Jewelry Resin, than immediately hold over your bezel and disperse. Repeat this process as required. You can also use a disposable plastic pipette, a plastic spoon or small squeeze bottle to easily fill your bezels with. Fill your pieces just slightly higher than the rim and your pieces will cure with a nice high dome. If desired, one can add another layer to create an even higher dome once this layer has set.

- Tip: If you overflow the bezel, just let it cure. Then after 12 hours of curing, the coating will reach a soft cure and trim easily. After 24 hours you may need to sand the excess material from the bezel.

Bubbles: EnviroTex Jewelry Resin has been formulated to self-degas within a few minutes of pouring under normal conditions. If after 25 minutes there are bubbles on the surface, remove them by gently blowing across the surface or gently through a straw. Be careful not to get too close with the straw as moisture from your breath can accumulate in the straw and cause water droplets to drip onto your work. A embossing heat gun also works well to remove bubbles. Be careful not to overheat your pieces.

Cure: For best results, jewelry pieces should cure at temperatures between 70°F / 21°C and 80°F / 27°C. Curing time will vary depending on room temperature and humidity. Warm, dry environments are best.

Trim and Sand Edges: Within 12 hours of applying, the coating will reach a soft cure and trim easily. After 24 hours use fine sandpaper to remove excess material. If necessary, touch up sanded areas with a brush and mixed EnviroTex Jewelry Resin.

Clean Up:

- Skin: Use warm water and liquid soap to remove from skin. Never use solvents or alcohol.

- Tools: While liquid, the material can be cleaned from tools with alcohol or solvent. Once cured, sand or scrape materials from tools.

Trouble Shooting:

- Soft and sticky cured surface: Is a result of improper mixing or inaccurate measurements of resin and hardener. The soft or sticky material must be removed and the area re-coated. Prevention: Do not guess at the proper ratio or just empty the two bottles into your mixing container. Use a proper measuring device and measure equal portions of resin and hardener. Always double mix as per the instructions.

- Note: Inadequate measuring and mixing is the most common reason for imperfect results.

- Cured pieces look cloudy: This is generally the result of mixing cold EnviroTex Jewelry Resin. Prevention: Warm EnviroTex Jewelry Resin as stated in the instructions prior to using.

- EnviroTex Jewelry Resin set before completely used: Often this is the result of mixed EnviroTex Jewelry Resin left sitting in a mixing container too long after mixing. Prevention: Always use EnviroTex Jewelry Resin immediately once mixed.

- Cloudy resin: Due to the purity of EnviroTex Jewelry Resin, a clouding or settling of the resin may occur from storing in cold conditions. This is a normal process and does not affect the outcome of this product. Should this occur, simply set the resin container in hot tap water until clear. Allow to cool before using. Prevention: Store in warm area.

Have a question regarding this project? Email Customer Service.

Copyright Permissions

All works of authorship (articles, videos, tutorials and other creative works) are from the Fire Mountain Gems and Beads® Collection, and permission to copy is granted for non-commercial educational purposes only. All other reproduction requires written permission. For more information, please email copyrightpermission@firemtn.com.