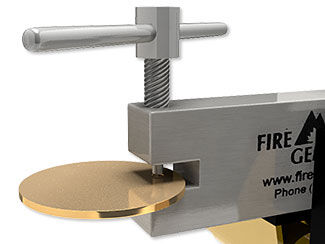

How to Use the Eyelet and Rivet Setting Tool

Silent animation displays how to use the eyelet and rivet setting tool to connect multiple layers of metal, leather or other materials for cold connection or mixed media designs. Below the video are full written step-by-step instructions.