Ask the Experts Glaze Q&A

I have a couple questions about Kato Polyclay. First, what adhesives would you recommend to use with the clay? I've noticed that some of them "eat" through the clay or make it soft and sticky again, and it might take a couple of weeks before you get such a "surprise." The last glue I've used was E6000® Jewelry and Craft Adhesive; no "surprises" so far. Are there any other adhesives which are safe for the polymer clay?

Second, is there any particular glaze which is best to cover cured polymer clay with? I've tried Sculpey®, but for some reason it sometimes forms little bubbles on the surface of the clay when dried. Thank you very much.

- Kelly

Devcon 2-part Jeweler's Epoxy is a good choice when adhering something, like a finding, to polymer clay. Signature Series Poly Bonder by Lisa Pavelka is another good choice for this application. Each of these offers the best long-term results. However, polymer clay is a non-porous surface and therefore the bond with any adhesive will erode over time, wear and tear.

When possible, it is best to embed findings and add polymer bezels around glass, gemstones or other inclusions. Please make sure that all inclusions are heat safe before baking in the oven at the recommended temperature. Once the inclusion is secure, bake in place following the manufacturer's recommended directions.

Kato Polyclay clear medium liquid can be used like a glaze. It is best to apply this product, and any glazing material with a good-quality paintbrush to help avoid creating bubbles and brush strokes. Kato Polyclay clear medium liquid is cured by baking, following the manufacturer's instructions.

Mona Lisa™ Metal Leaf™ topcoat sealant offers a shiny, smooth finish on polymer clay. It is cured by air drying.

Over time, wear and tear you may find the finish for each of these diminishes or flakes off; they can be reapplied, if necessary.

Sanding, polishing and buffing the surface of polymer clay will yield a shiny finish that will last a long time as well as one that will be enhanced over time with wear. Sanding and polishing the surface using all grits of sandpaper followed by polishing papers will yield a smooth and shiny surface. For an even greater shine, buff the surface with a muslin wheel fitted to a Foredom® Bench Lathe or the flex shaft of a rotary drill.

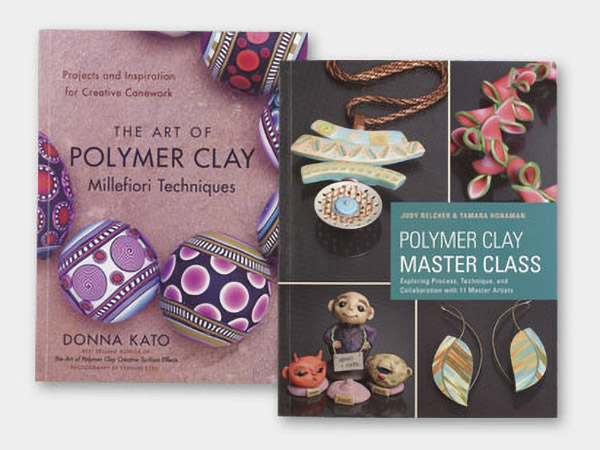

- Tammy Honaman, Author, Jewelry-Making Expert and Educator

Still can't find what you're looking for?

Submit Your Question