Choosing a Wireworking Wire

Choosing the best wire for your project makes it that much easier to achieve your goals in the exciting art of wireworking. Understanding some key points about choosing wireworking wire—hardness, gauge and more—will help you on your journey to being the best designer you can be!

Can All Jewelry-Making Wire be Hammered?

Most can be. Color-coated wire should be hammered gently and minimally to reduce the risk of the color coating cracking. Here's a quick guide:

Safe to Hammer

- Gold-Filled – Malleable and gorgeous; one of the best wires to texture

- Sterling Silver or Sterling Silver-Filled – Great for shaping and adding shine; robust and beautiful

- Copper – Soft, easy to texture and flatten

- Brass – Harder to work with but adds bold texture

- Aluminum – Very soft; hammer lightly

Use Caution

- Plated or Finished Wire – The outer coating can crack or flake

- Stainless Steel – Difficult to shape

- Niobium Wire – Can work-harden too quickly and any anodized coating can become marred

- Color-Coated Craft Wire – Hammer gently and minimally. Coating my stretch and crack if hammered too much

Thicker wire (16- to 20-gauge) is best for hammering. Thinner gauges of wire can tend to break or become flat instead of acquiring texture. Use a flat hammer for a polished finish or a textured hammer for more detail. Be sure to straighten and smooth the wire before hammering and be sure to wear eye protection!

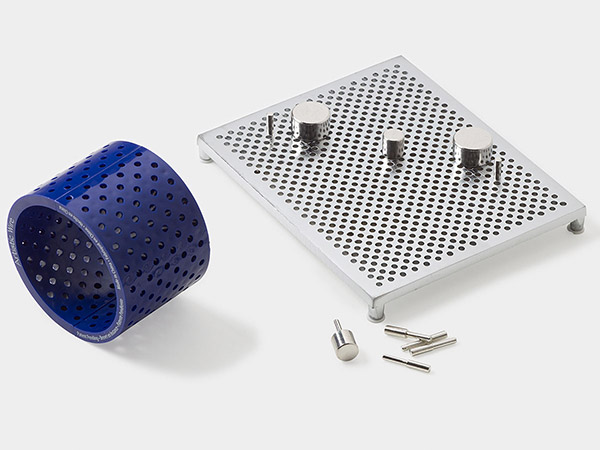

Tip: If you’re unsure, test a scrap piece first. Always hammer on a steel block using a chasing or ball peen hammer for best control and effect.

For more information about preparing metal for hammering and creating a variety of patterns, read “How to Anneal and Texture Metal.”

Wireworking FAQ

Q: What gauge wire is suitable for wrapping?

A: Any gauge wire can be used for wire wrapping. Your project and materials will dictate the appropriate gauge and metal type to use. For instance, thin wire (28- to 30-gauge) can be used to wrap tiny beads. Earring components are usually created with 18- to 22-gauge wire, but it can also be used to wrap larger beads to create a more rugged look, or it can be hammered or polished to create different vibes. Experiment with various gauges to see what you prefer.

Q: Can you solder wireworking wire?

A: It is possible to solder wireworking wire. For tips on soldering, read “Soldering Savvy” and “The Differences Between Soft and Hard Soldering.”

Q: What is the best gauge of wire to use when making a ring?

A: Heavier gauges of wire—14- or 16-gauge—are best for creating rings. They will hold their shape better than thinner wires.

Q: What does work hardening mean?

A: “Work hardening” means changing the hardness of metal by manipulating it—stretching, twisting, tumbling and others. To learn more about work hardening, read “Work Hardening Metal” by expert jewelry maker, Tamara Honaman.

Q: Can I use my home hammer to hammer wire?

A: It is not recommended to use a home hammer to hammer jewelry-making wire. Hammers designed for jewelry making are less likely to damage or break the wire, and they will produce more consistent, aesthetic results.

Q: Which wire type is best for designers getting started with wire?

A: Round wire is the most forgiving wire type. Save square wire and other shapes for when you have more experience manipulating wire.

For more information you may find helpful to your wireworking journey, read “Wireworking Tips: Wire Coils, Pliers and Jigs.”

Shop for Your Materials Here:

Have a question regarding this resource? Email Customer Service.

Copyright Permissions

All works of authorship (articles, videos, tutorials and other creative works) are from the Fire Mountain Gems and Beads® Collection, and permission to copy is granted for non-commercial educational purposes only. All other reproduction requires written permission. For more information, please email copyrightpermission@firemtn.com.