All About Crimps

By Jean Campbell, Exclusively for Fire Mountain Gems and Beads®

Crimps may be small in size, but they are "super findings." Crimps are metal and mighty-- holding stringing materials and beads together in jewelry designs. They are THE finding to keep your stringing projects intact, the "glue" that keeps a design together and can even be counted on to add flash to a design. The term "crimping" means to join two or more pieces of metal or other material by deforming one or both to hold the other. This bend or deformity is known as the "crimp."

Discover the history of crimps, the difference between crimp tubes and crimp beads, how to crimp like a pro and how to use crimp covers in this jewelry maker's crimp guide. Find FREE video tutorials to perfect your crimping technique and a handy reference chart for choosing the correct crimp sizes for any project.

Here are some materials you'll want to have ready at your fingertips:

- Crimp beads or crimp tubes

- Crimp pliers

- Accu-Guard™ wire protectors

- Accu-Flex® professional-quality beading wire

- Crimp covers

History of Crimps

In the previous century, attaching stringing material to a clasp for even a simple necklace or bracelet was involved and time consuming. First, you had to string a short, coiled wire called bullion (or gimp or French wire) so the thread wouldn't wear against the metal. Then you'd pass through the clasp, back down into the beads, tie a knot, pass through a few more beads, tie a knot, and on, and on and on.

People still make jewelry the old-fashioned way, but at least now there's another option: crimp beads or crimp tubes, beading wire, Accu-Guard wire protectors and crimp covers. This no-muss, no-fuss way of stringing beads makes it easy for even the least dexterous of us to make professionally finished jewelry for long-lasting wear.

The advance of this technique has made it possible not only for the jewelry industry to churn out affordable accessories, but it has also made it possible for everyday craftspeople to easily create their own jewelry. The type of crimp beads initially used had a serrated hole that grabbed onto the wire when squeezed with chain-nose pliers. The wire primarily used, Tigertail™, was strong and durable, but pretty stiff and prone to kinking. This scenario was standard until sometime in the early 1990s. Since then, the advance in beading wire technology has been phenomenal. The different wire colors, flexibilities and thicknesses have increased jewelry design options incredibly.

Top-rated Accu-Flex professional-quality beading wire is strong, flexible, kink-resistant and easy to crimp. It utilizes advanced wire-bundling technology, resulting in increased strength and durability, while still maintaining flexibility for a nice drape.

Crimps have come a long way from the days of the little round piece of metal you "crush flat" to secure inflexible beading wire. The types of crimps available have also expanded.

No longer alone is the crimp bead. Now we have the crimp tube, an item that won't bite into wire and weaken it. Also available are crimps with built-in loops and clasps, large cord crimps, Screw-Tite Crimps™ and crimps with stamped designs

How to Crimp

Crimp Beads vs. Crimp Tubes

Crimp beads resemble a hollow round bead and come in a variety of metals and sizes. They are secured to jewelry-making wire by flattening the crimp bead with a pair of flat or chain- nose pliers. The flattened crimp bead grips the wire for a secure finish. You want to avoid squeezing the crimp bead too hard as it can break or be weakened and can also bite into the jewelry wire itself, causing it to break or fray.

Crimp tubes, also referred to as crimp beads, are sections of tubing (typically seamless) that are intended to be used when finishing beading wire, like Accu-Flex® professional- quality beading wire. The end of the beading wire is passed through a crimp; through a loop on your clasp, or other finding like a soldered jumpring or Accu-Guard™ Wire Protector; passed back through the crimp and then drawn taut. Crimping pliers are then used to crimp the bead to secure it. These pliers are expressly designed for use with crimp beads and tubes, utilizing a 2-step process for creating a very secure finish to your design.

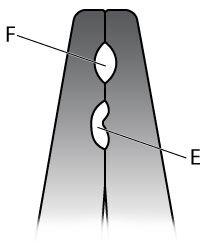

The crimping pliers' first station (E) puts a crimp in the crimp tube, forms the crimp into a crescent moon shape and compresses the crimp over and between the wires captured inside. The second station (F) folds the crimped tube in half, gripping the jewelry wire. The crimp is rounded with the front notch of the pliers to round the crescent-shaped tube into a "bead." You don't need to use a lot of force with crimping pliers, it doesn't take much force to compress a crimp tube. After you round the crimp tube you can go around the crimp several more times to mold it into the perfect shape and ensure it is snugly attached to the jewelry-making wire. Learn more about crimp tubes in Fire Mountain Gems and Beads' FREE article on ''Crimp Tubes''. View a FREE video tutorial on ''How To Crimp a Crimp Bead/Crimp Tube'' to practice this essential jewelry-making technique.

Screw-Tite Crimps offer another secure way to connect your beading wire to a finding, such as a clasp. What makes this style crimp different from other crimps is that it is secured in place with a set screw. And not only is this crimp secure, it can also be removed at any time. This feature allows you to change your beaded design or clasp, should you decide you want a different look. Screw-Tite Crimps require the Screw-Tite Crimps™ screwdriver set to use. View Fire Mountain Gems and Beads' FREE video tutorial on ''Crimping with Screw-Tite Crimps™''.

Choosing the Right Size Crimp Tubes

When deciding which type and size of crimp tubes to use, it's important that you know the wire thickness you'll be using for your piece. You'll also need to have a general idea of your design. For instance, if you're making a double-stranded piece and the two strands will eventually be secured by the same crimp, the crimp will need to be wide enough, not only to take the first two strands, but also to accommodate the two strands when they pass through the clasp again. Fire Mountain Gems and Beads offers a FREE chart for finding the right size crimp beads based on the number of strands and diameter of beading wire used.

Crimp tubes are measured length by outside diameter (OD), i.e. 3x2mm means 3mm long by 2mm around. You will also see the inside diameter (ID) measurement noted, which indicates the inside space of the crimp and how much room there is for your stringing material. In most cases, a larger ID indicates a larger opening, where the smaller the opening indicates a thicker crimp wall and a stronger crimp hold, i.e. 2x2mm sterling silver crimp with a 1mm ID has a thicker wall than a 2x2mm crimp with a 1.3mm ID. You want your crimp to succeed so choose the right size but also the thickest metal possible.

Generally speaking, a 1mm OD crimp tube of any length is great for use with finer strands of beading wire (.007 to .014), 2mm OD crimps are ideal for .019 and the 3mm OD crimps for the heavier .024 beading wire. This general rule is based on passing the beading wire through the crimp bead twice.

| Wire: |

| .014" Accu-Flex beading wire x (2) passes through a crimp .028" needed inside diameter |

This scenario allows enough room for the crimp to compress over and between the wires captured inside and hold them in place, rather than filling the crimp to a point where one length of wire can slip against the other and subsequently out of the crimp.

Here is a chart that includes inside diameters of crimp tubes for easy reference.

Inside opening = inside diameter (ID)

1 inch = 25.4mm

1mm = .0394 inches

Crimp Tubes/Crimp Beads | ||

| Size (mm) | Material | Inside Diameter (mm) |

| 1x1 | Sterling Silver | 0.76 |

| 2x1 | Gold-Filled | 1.5 |

| Sterling Silver | 0.76 1 1.1 | |

| 2x1.5 | Gold-Filled | 1.3 |

| Sterling Silver | 1.3 | |

| 2.5x1.5 | Copper-Plated | 1.2 (corrugated) |

| Gunmetal-Plated | 1.2 (corrugated) | |

| 2x2 | Gold-Filled | 1.1 |

| Copper | 1.2 | |

| Sterling Silver | 1.2 1.3 1.4 | |

| 2.5x2 | Gold-Filled | 1.5 |

| Silver-Plated | 1.5 | |

| Black-Plated | 1.5 | |

| 3x1.5 | Sterling Silver | 1.1 |

| 3x2 | Gold-Plated | 1.4 |

| Silver-Plated | 1.4 | |

| Gold-Filled | 1 (twisted) | |

| Sterling Silver | 1 1 (twisted) 1.3 | |

| 3x3 | Sterling Silver | 2.5 |

| 4x2.5 | Sterling Silver | 1 |

| Brass | 1 | |

| Copper-Plated | 1 | |

| 4x4 | Sterling Silver | 3.5 |

| 5x3 | Sterling Silver | 1.3 1.7 |

| 5.5x2.5 | Copper-Plated | 2 |

| 5.5x3 | Sterling Silver | 1.5 |

| 6x3 | Copper | 2.25 |

| Sterling Silver | 2.5 | |

| 6x4 | Sterling Silver | 2.5 |

| 6.5x6 | Brass | 4 |

| 13x2 | Sterling Silver | 1.4 |

Crimp Covers and Accu-Guard Wire Protectors

The jewelry-maker's secret to disguising crimped crimp beads are with large-holed beads or crimp covers. Choose the crimp covers in the metal and size that suits your design--3mm crimp covers work well at covering most 1x1mm-2x3mm crimps. However, if your design has 4mm metal beads in it then you may prefer to use 4mm crimp covers. View a FREE video tutorial on ''Using Crimp Covers'' for a professional-looking finish.

Protect Accu-Flex professional-quality beading wire against wear from clasps and other sharp-edged components with Accu-Guard™ wire protectors. These wire protectors are like bullion or French wire, but in a pre-curved horseshoe shape. View Fire Mountain Gems and Beads' FREE video on ''Using Accu-Guard™ Wire Protectors''.

Fire Mountain Gems and Beads offers many FREE how-to video tutorials on crimping including crimping with crimp tubes, using crimp covers, how to crimp a crimp bead, crimping tools that make crimping easier and a helpful crimp sizing chart for selecting the right size crimp for your jewelry-making project.

Have a question regarding this project? Email Customer Service.

Copyright Permissions

All works of authorship (articles, videos, tutorials and other creative works) are from the Fire Mountain Gems and Beads® Collection, and permission to copy is granted for non-commercial educational purposes only. All other reproduction requires written permission. For more information, please email copyrightpermission@firemtn.com.